5 Symptoms of a Bad Secondary Air Injection Pump

If you’re wondering what a secondary air injection pump is, you’re not alone. In this article, we’ll explain the purpose of a secondary air pump and the symptoms you should look for to know that your pump is failing.

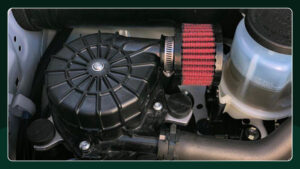

The secondary air injection pump is essential for controlling emissions and maintaining optimal engine performance. If this pump doesn’t work properly, several issues can occur that affect both your driving experience and the environment. Learn the signs of a bad secondary air injection pump, what causes it to fail, and how much it might cost to replace it. What does a secondary air pump do? A secondary air injection pump (also known as a smog pump or SAI pump) serves to reduce carbon emissions emitted from a vehicle’s exhaust. This is necessary because 100% efficiency is never achieved during the combustion process in a vehicle engine.

This pump is located behind the vehicle’s exhaust manifold and before the catalytic converter, and helps reduce carbon emissions by pumping fresh air from outside into the exhaust stream. When the exhaust gases leave the tailpipe, they contain fewer hydrocarbon pollutants. This reduces outdoor air pollution and contributes to a safer environment.

If there is a problem with your secondary air injection pump, you will end up with many more hydrocarbon contaminants in the exhaust gases leaving your tailpipe. This will only be obvious if you run an emissions test.

If you don’t, you will experience a host of unfortunate symptoms that affect your engine. Neither scenario is what you want. Doing so can make your life pretty difficult.

The 5 Most Common Symptoms of a Faulty Secondary Air Injection Pump

Secondary air injection pump failure is easy to detect if you know what symptoms to look for. Below are the 5 most common symptoms of a faulty secondary air injection pump.

If you notice at least two symptoms, your secondary air injection pump is likely bad and should be repaired immediately.

1) Check the Engine Light

One of the first symptoms of a faulty secondary air injection pump is the check engine light coming on. The engine control unit can automatically detect if there is a problem with the secondary air injection pump.

Because the operation of the air pump affects the engine, any abnormality will cause the engine check light on the dashboard.

To find out the actual cause of the engine check light, you need to use your car’s code reader to retrieve all stored trouble codes. Codes P0410 and P0411 are common trouble codes related to the secondary air injection pump.

2) Failing an emission test

The purpose of the secondary air injection pump is to reduce hydrocarbons in the exhaust system. So if your secondary air injection pump is defective, it means that your exhaust system is releasing a lot of hydrocarbons into the atmosphere.

This is not only an environmental issue, but also an emissions testing issue. If you live in a state that requires emissions testing, a defective secondary air injection pump will cause you to fail the test.

3) Weak Acceleration

A failed secondary air injection pump causes problems with the air-to-fuel ratio of your internal combustion engine. If this ratio is too lean (not enough fuel), your engine will have a hard time picking up speed when you step on the accelerator. Poor acceleration can have a variety of mechanical causes, but a defective secondary air injection pump is certainly a possibility. A failed emissions test combined with weak acceleration is a good sign that the pump is defective.

4) Engine Stalls

You may be driving normally and then suddenly your engine stalls or your car sputters. A worn out secondary air injection pump can cause your engine to lose power erratically.

One minute it’s performing well, and the next it’s slowing down too much and stalling out. If the pump is not replaced, the engine may repeatedly stall at the most inopportune times.

5) Low Idle

When your engine is idling, check the tachometer to see the current RPM. The normal speed of an idling engine is between 600 and 1,000 rpm. However, in a situation where the secondary air injection pump is not functioning, you can expect the RPM to drop. This can cause your car to shudder or stall as explained above.

If you are already experiencing symptoms such as engine stalling, poor acceleration, or an illuminated check engine light, you should have your secondary air injection pump inspected immediately. If this proves to be the problem, have it replaced by a certified mechanic.

Possible Causes of Failure

1) Effects of Aging and Heat

As vehicles get older, components such as the secondary air injection pump become more susceptible to wear. The pump’s internal parts wear over time, which can affect performance or cause complete failure.

In addition, excessive heat can accelerate pump failure. If the cooling system is not properly maintained, high temperatures can damage the pump’s components. To avoid problems due to aging and wear, it is important to properly maintain your vehicle and monitor the lifespan of your pump.

2) Control and Vacuum Issues

Secondary air injection pumps require additional components such as a control valve and vacuum system to function properly. The control valve controls the flow of air from the pump. If it malfunctions or becomes damaged, it can cause pump failure. Similarly, problems with the vacuum system that operates the pump can lead to pump failure. A V-belt drives the pump through the motor drive system. Over time, the belt can wear or become damaged. This can cause the secondary air injection pump to lose drive power. In some cases, simply replacing a worn belt may be enough to restore proper operation of the pump.

3) Clogging and Leaking

Clogging can occur in the hose, air filter, or pump inlet. These blockages can prevent proper air flow to the pump, leading to failure.

Leaks can also develop in the system, causing loss of vacuum and problems with the control valve. Leaks prevent the pump from maintaining the required pressure.