5 Symptoms of a Bad Crankshaft Position Sensor

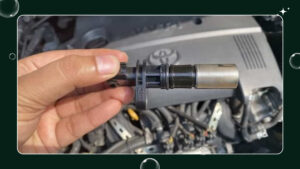

The crankshaft position sensor is installed in almost every new car on the road today. Its job is to track the position and speed of the crankshaft. The crankshaft position sensor then sends this data to the engine control unit (ECU).

Based on this information and current operating conditions, the engine control unit adjusts the amount of fuel injected into the combustion chamber, which also affects the timing of the ignition system. An automobile’s internal combustion engine consists of a crankshaft and pistons. These two parts, along with other components, start the engine and generate the power needed to move the vehicle.

When fuel and air burn in the combustion chamber, the steam exerts pressure on the pistons. As this happens, the crankshaft converts this pressure into rotational energy. To do this properly, the crankshaft must be in the correct position and spinning at the correct speed. The role of the crankshaft position sensor is basically to detect the position of the crankshaft and its rotational speed.

Why is this important? These are all vital pieces of information that the ECU needs to properly control the combustion process.

Then the ignition system has to find the right moment to ignite the mixture. Failure to do so can affect engine performance.

The crankshaft position sensor allows the engine control unit to get precise information about the crankshaft. This way, your vehicle’s computer tells the injectors to inject the exact amount of fuel required into the chamber.

If the crankshaft position sensor does not work as intended, it will cause problems with the operation of your engine and vehicle. Below are the 5 most common signs that indicate a bad crankshaft position sensor. If you detect two or more of them, you may want to take your car to a mechanic as the cause may simply be the sensor.

1) Irregular Stall (Engine Stall)

The crankshaft position sensor is made up of a number of cables that run to the engine control unit and the crankshaft. If one of these cables becomes damaged or worn, the engine control module will no longer be able to receive data signals from the sensor.

Driving your car in this condition may cause the engine to stall. It may stop all the time or at irregular intervals.

2) Vehicle is difficult to start (Car won’t start)

If the crankshaft position sensor is broken or damaged, the first thing you will notice is that your vehicle is difficult to start. For the engine to start properly, the crankshaft needs to have the right speed and position.

If the engine control module is not receiving accurate information about the crankshaft, you will have trouble starting your vehicle. In some cases, you may not be able to start the car at all.

3) Engine vibration (How does a gasoline engine work?)

If the crankshaft position is not monitored carefully, it can cause problems with the engine. The reason is that the engine cannot control its performance and severe vibrations can occur.

4) Hesitation when accelerating (hesitation of the accelerator pedal when accelerating)

If the crankshaft position sensor is bad, it takes time for the engine control module to receive this information, which means you’ll experience delayed and unresponsive acceleration every time you step on the accelerator.

5) Check Engine Light (Oil Pressure Check Engine Light)

There are over 100 reasons why the check engine light may come on. One of these reasons is a faulty crankshaft position sensor. If the engine control module doesn’t receive a proper signal from the sensor, it thinks something is wrong and may automatically illuminate the check engine light on your dashboard. When scanning for trouble codes with an OBD2 scanner, you may see codes related to the crankshaft position sensor, such as: B. P0335 or P0340.